Emerson

UX and Usability in Industrial Products

- UX/UI Design,

- Design System,

- User Research

About the project

We are very proud to have been working with Rosemount Tank Radar AB, part of Emerson, since 2021 to improve the user experience of their digital products. Rosemount Tank Radar AB develops radar-based level measurement products used globally to measure liquid and material levels in tanks, reactors, and mixers across industries such as chemicals, water, oil & gas, and food & beverage. More information can be found at Emerson.com. The collaboration is carried out through DevPort, an approved consulting partner to Emerson. Emerson’s products are built to perform under all conditions, robust, reliable, and technically advanced. Our role is to work together with Emerson’s teams to ensure that the software supporting these products is perceived in the same way: intuitive, accessible, and consistent, even in complex industrial environments.

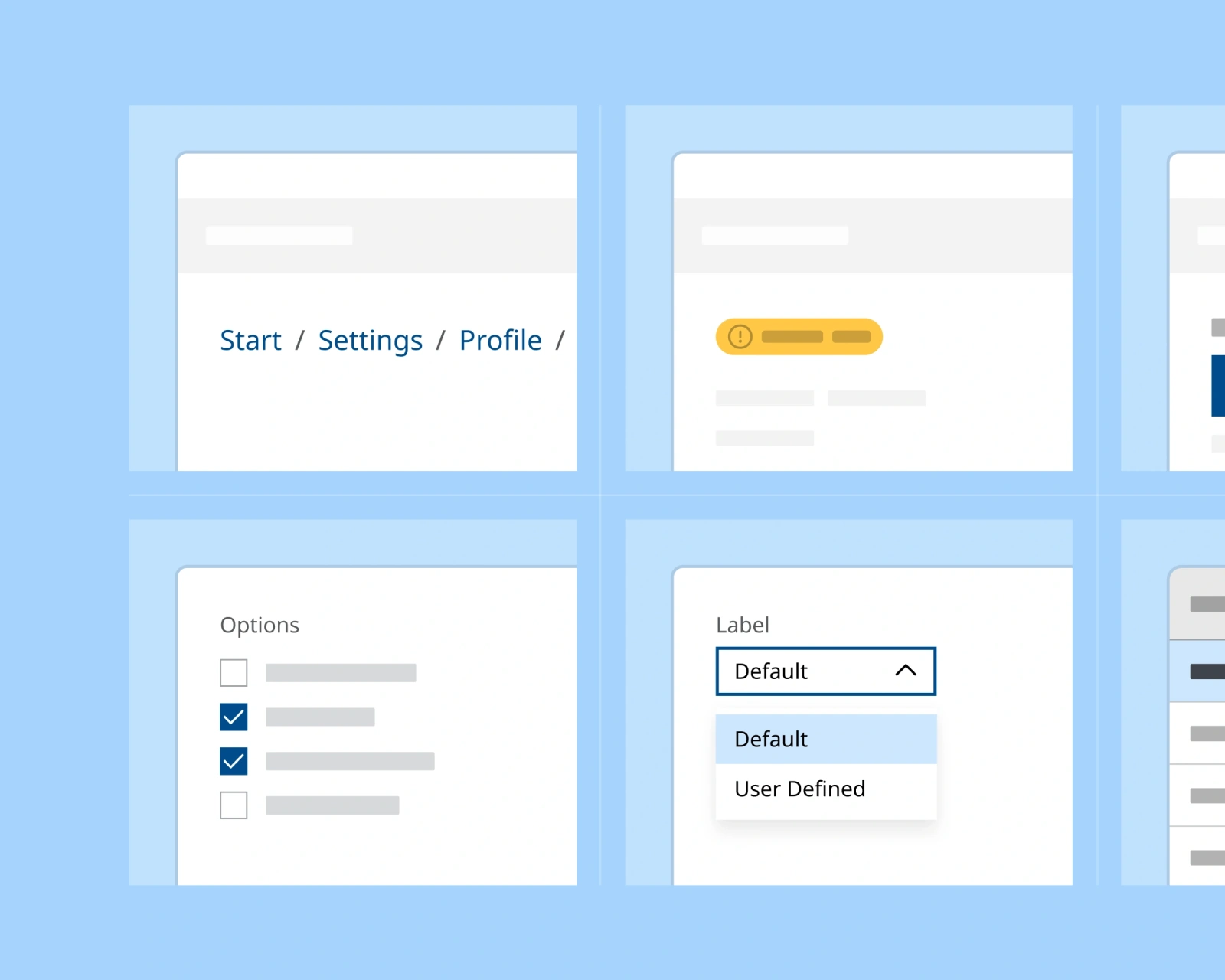

A Shared Design System

To create a consistent experience across Emerson’s software products, we have jointly established a shared design system. It provides structure, consistency, and enables teams around the world to work toward the same goals. The design system serves as the foundation for the digital platforms developed by Rosemount Tank Radar AB and is currently used in the development of several new products. It allows each product to feel unique while still being part of a cohesive whole. Where design, usability, and technology come together efficiently.

Our primary responsibility at Emerson is UX and product design for configuration tools and monitoring solutions. One of the first products we helped design using the shared design system was a new configuration tool for Emerson’s non-contacting radar products. The goal was to create a simple, modern, and intuitive user experience for a product based on highly advanced measurement technology. The interface is designed with clear navigation based on familiar design patterns from modern desktop and mobile applications, allowing users to quickly feel at home and focus on the configuration task itself.

The design emphasizes high readability and optimized contrast for both bright and dark environments. It follows guidelines such as WCAG 2.0 and NAMUR NE-107, ensuring that the application meets requirements for accessibility, safety, and industrial standards. The work demonstrates how a shared design system can make development more efficient, improve quality, and create a consistent experience across products and platforms. While also showing how UX can make advanced technical tools easier to understand and use.

Designing good UX for industrial environments is a complex task. The instruments are technically advanced, safety standards govern parts of the process, and compatibility with other systems limits how functionality can, and must, be designed. For us as designers, this introduces a set of unique challenges, both in understanding user needs and in creating solutions that work in practice. UX in industrial contexts is often about making complexity understandable without simplifying what is essential. Operators and technicians are experts in their instruments and processes, and the systems they work with contain a large number of settings, parameters, and dependencies. Our role is to create structure, clarity, and focus. A logical navigation where the right information is presented at the right time, in a way that supports decision-making.

We work closely with product owners, engineers, and end users to ensure that every design decision works in real-world use, not just in theory. Good industrial UX rarely involves dramatic visual changes. Instead, it is about precision in the details. When flows become clearer, information more relevant, and systems easier to interpret, the difference is noticeable in daily work. Through fewer errors, shorter learning curves, and increased confidence in use.

To understand how Emerson’s products are used in real-world settings, we conduct ongoing UX research, with interviews, customer dialogues, and workflow analysis forming the foundation. By talking to operators, technicians, and installers, we gain insight into their work, goals, frustrations, and priorities — insight that no documentation or internal discussion can fully replace. Interviews help us understand why people work the way they do, how they think, which decisions they make, and what matters most in their daily work. Observations complement this understanding by showing how work is actually carried out. This is especially important in environments with specific constraints. Such as process plants, Ex-classified zones, or settings where safety regulations restrict how systems can be used. It may also involve situations where equipment must be handled while wearing gloves, or where time pressure and physical conditions influence work practices.

The most valuable insights emerge at the intersection of what people say and what they do. These insights might reveal why certain settings are always prioritized and perceived as critical, which functions create stress under time pressure, or why specific steps are experienced as unnecessarily complex. Such issues rarely surface in internal reviews, yet they directly impact usability, efficiency, and safety. Insights are analyzed and visualized through methods such as user journeys, hierarchical task analysis, workshops, and early prototypes. This ensures that design decisions are based on real behaviors, needs, and goals. Not assumptions. Industrial UX research is therefore not only about understanding how systems should be designed, but about understanding people, their work, and the decisions they make in real life.

Accessibility is a central part of Emerson’s design work, and something we actively contribute to developing. We do not see accessibility as a separate requirement, but as a prerequisite for quality. By addressing accessibility from the very first design sketch, we work together with Emerson to ensure that products function for all users, regardless of conditions or environment. The work follows WCAG 2.0 guidelines and covers everything from color contrast and typography to information hierarchy and interaction patterns. The goal is not only to meet standards, but to create interfaces that are clear, safe, and easy to read in all situations. From dark control rooms to bright sunlight in the field.

In practice, accessibility means designing for robustness and predictability. This makes products easier to use, reduces the risk of errors, and strengthens trust in the system. Good accessibility is therefore not only about inclusion, but also about operational reliability and long-term quality.

Partnership as a Way of Working

Our collaboration with Emerson is built on long-term commitment and trust. We work as an integrated part of their teams, with shared goals, tools, and processes. Our responsibility spans from early user research and design strategy to implementation, testing, and continuous improvement. Working with industrial products involves long development cycles. It requires endurance, accountability, and the ability to stand by decisions even as conditions change. For us, this work is about more than delivering design solutions. It is about being a reliable partner who follows projects over time, maintains previous decisions, and continuously drives development forward as products and the organization evolve. We see design as an organizational capability — one that influences processes, culture, and decision-making. A way to create structure, build alignment, and maintain a coherent product experience over time. Our goal is to help make UX a natural part of how Emerson thinks, builds, and improves its products.

words from the team

❝ The team has overall responsibility for UX and is involved in how products are shaped and implemented. Through close collaboration between design, engineering, and the business, we ensure that the user perspective is embedded throughout the entire process.

Do you like what we do?

Don't hesitate to share your next idea with us. We'd love to learn more about you and what we can create together.

Related Work

Emerson Design System

Swanholm Technology